- LIFTING EQUIPMENT (136)

- Aardwolf Slab Lifters (13)

- Slab Lifters (21)

- Vacuum Lifters (60)

- Vacuum Tube Lifters (3)

- Box Lifting Clamp (1)

- Drum Lifters (1)

- BAG LIFTERS (1)

- Rock Lifters (3)

- Brick Lifters (2)

- Pipe Lifters (6)

- Glass Lifters (3)

- Load Handling Attachments (4)

- Slab Bundle Handler (3)

- Stone Carrying Hand Clamps (5)

- Hand Vacuum Cups (5)

- Cargo Lashings & Slings (5)

- Jib Cranes (14)

- FORKLIFT EQUIPMENT (27)

- SLAB & BUNDLE RACKS (26)

- A-FRAMES (45)

- TROLLEYS (18)

- WORKBENCHES & STANDS (28)

- WORKSHOP EQUIPMENT (54)

- ADHESIVES (0)

- Diarex (8)

- Workwear (14)

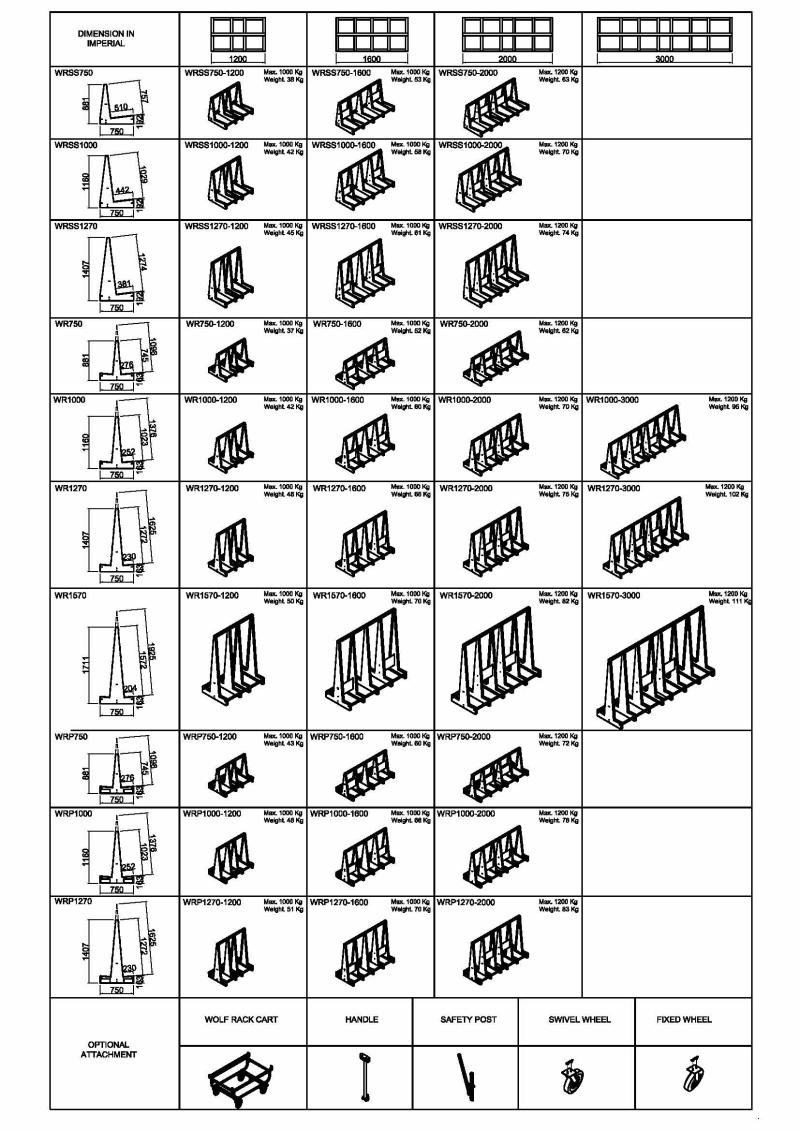

Wolf Rack

General

The Wolf Rack has an A-frame structure that is manufactured from 2mm thick sheet metal. The frames have an open structure. The tops of the individual A-frames contain rivet nuts and are bolted into a U-shaped tie bar with self-aligning bolts, while load bars are fitted into slots at the base of the A-frames on each side. The load bars are also fastened by self-aligning bolts screwed into rivet nuts, which are permanently fixed at the base of the A-frames. This produces a rigid connection and allows assembly without special skills and only one tool.

Features

- The Wolf Rack transport racks include a number of modular A-frames formed from 2 mm sheet metal secured to one another.

- Frame-bearing surfaces are rubber topped, sloping inwards, while perpendicular support surfaces are cushioned with resilient rubber material to provide protection to and retention of the materials loaded upon the transport racks

- The bearing surfaces are configured to be as low as possible in the A-frame of the Wolf Rack transport rack so as to provide a minimal lift height for loading and unloading while at the same time-space is also available for the forks of a forklift truck and pallet jacks.

- The Wolf Racks are lightweight yet strong and are easily and quickly assembled and disassembled.

- The Wolf Rack has an A-frame structure that is reducible to a compact empty shipping size by one worker using one tool.

- The Wolf Racks are assembled from a few parts, reducing the assembly and disassembly time and making the operation simple.

- Further, the compacted Wolf Racks are light so that they can be manhandled into a van or onto a truck for return shipping.

Options:

- Optionally includes clip-on safety posts, which urge the carried objects against the A-frame assembly to provide for secure transportation of large objects, such as stone and glass sheets, while being moved on the concrete floor in factories and on construction sites.

- It also optionally includes quick-fit wheels and handles by using the same bolts and tools used to assemble the frame.

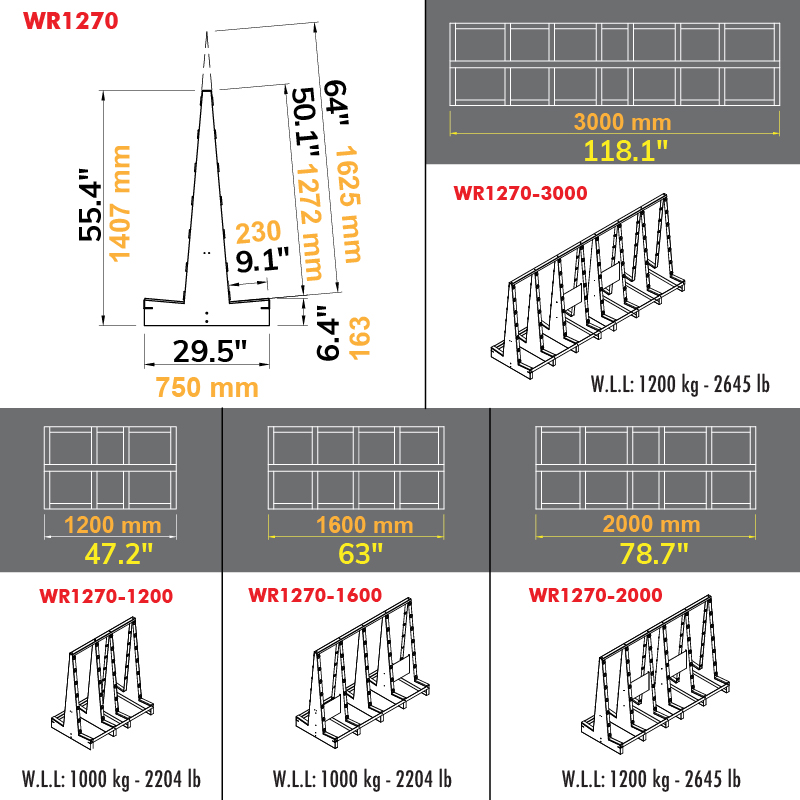

- Aardwolf offers many types of Wolf Racks, such as WR1270-1200, WR1270-1600, WR1270-2000, and Wolf Rack Pocket models such as WRP1270-1200, WRP1270-1600, WRP1270-2000.

Specifications

WR1270-1200:

|

Metric

|

Imperial

|

|

| Working load limit | 1000 kg | 2204 lb |

| Width of each side | 230 mm | 9" |

| Weight | 48 kg | 106 lb |

| Dimension | L.1200xW.750xH.1625 mm | L.47.2"xW.29.5"xH.64" |

WR1270-1600:

|

Metric

|

Imperial

|

|

| Working load limit | 1000 kg | 2204 lb |

| Width of each side | 230 mm | 9" |

| Weight | 65 kg | 143 lb |

| Dimension | L.1600xW.750xH.1625 mm | L.63"xW.29.5"xH.64" |

WR1270-2000:

|

Metric

|

Imperial

|

|

| Working load limit | 1200 kg | 2645 lb |

| Width of each side | 230 mm | 9" |

| Weight | 75 kg | 165 lb |

| Dimension | L.2000xW.750xH.1625 mm | L.78.7"xW.29.5"xH.64" |

Patent Pending

Volume: 0.0000 M3

General

The Wolf Rack has an A-frame structure that is manufactured from 2mm thick sheet metal. The frames have an open structure. The tops of the individual A-frames contain rivet nuts and are bolted into a U-shaped tie bar with self-aligning bolts, while load bars are fitted into slots at the base of the A-frames on each side. The load bars are also fastened by self-aligning bolts screwed into rivet nuts, which are permanently fixed at the base of the A-frames. This produces a rigid connection and allows assembly without special skills and only one tool.

Features

- The Wolf Rack transport racks include a number of modular A-frames formed from 2 mm sheet metal secured to one another.

- Frame-bearing surfaces are rubber topped, sloping inwards, while perpendicular support surfaces are cushioned with resilient rubber material to provide protection to and retention of the materials loaded upon the transport racks

- The bearing surfaces are configured to be as low as possible in the A-frame of the Wolf Rack transport rack so as to provide a minimal lift height for loading and unloading while at the same time-space is also available for the forks of a forklift truck and pallet jacks.

- The Wolf Racks are lightweight yet strong and are easily and quickly assembled and disassembled.

- The Wolf Rack has an A-frame structure that is reducible to a compact empty shipping size by one worker using one tool.

- The Wolf Racks are assembled from a few parts, reducing the assembly and disassembly time and making the operation simple.

- Further, the compacted Wolf Racks are light so that they can be manhandled into a van or onto a truck for return shipping.

Options:

- Optionally includes clip-on safety posts, which urge the carried objects against the A-frame assembly to provide for secure transportation of large objects, such as stone and glass sheets, while being moved on the concrete floor in factories and on construction sites.

- It also optionally includes quick-fit wheels and handles by using the same bolts and tools used to assemble the frame.

- Aardwolf offers many types of Wolf Racks, such as WR1270-1200, WR1270-1600, WR1270-2000, and Wolf Rack Pocket models such as WRP1270-1200, WRP1270-1600, WRP1270-2000.

Specifications

WR1270-1200:

|

Metric

|

Imperial

|

|

| Working load limit | 1000 kg | 2204 lb |

| Width of each side | 230 mm | 9" |

| Weight | 48 kg | 106 lb |

| Dimension | L.1200xW.750xH.1625 mm | L.47.2"xW.29.5"xH.64" |

WR1270-1600:

|

Metric

|

Imperial

|

|

| Working load limit | 1000 kg | 2204 lb |

| Width of each side | 230 mm | 9" |

| Weight | 65 kg | 143 lb |

| Dimension | L.1600xW.750xH.1625 mm | L.63"xW.29.5"xH.64" |

WR1270-2000:

|

Metric

|

Imperial

|

|

| Working load limit | 1200 kg | 2645 lb |

| Width of each side | 230 mm | 9" |

| Weight | 75 kg | 165 lb |

| Dimension | L.2000xW.750xH.1625 mm | L.78.7"xW.29.5"xH.64" |

Patent Pending

Volume: 0.0000 M3